- On sale!

- -€10.00

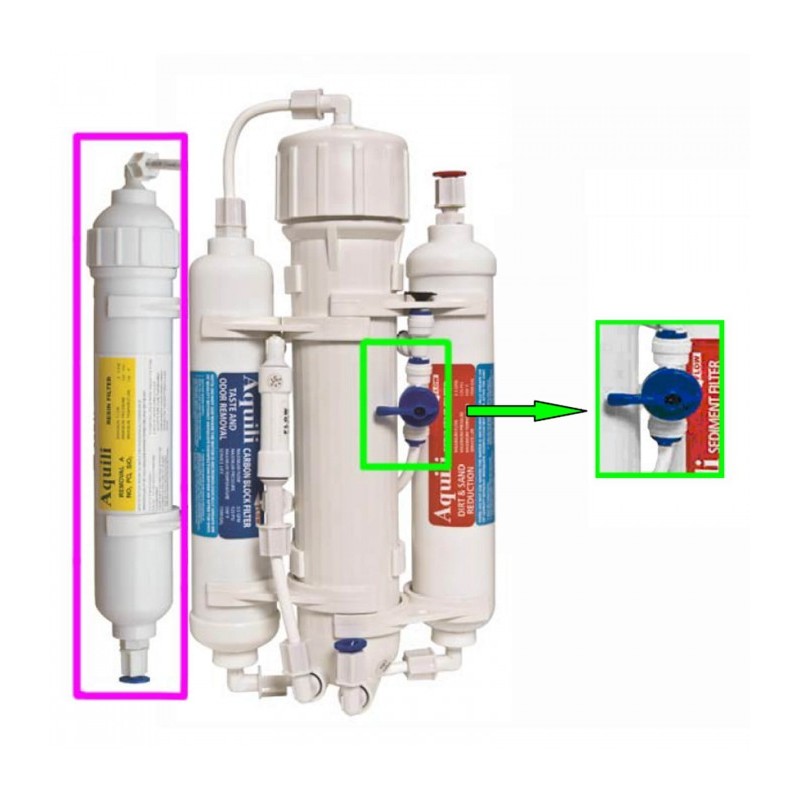

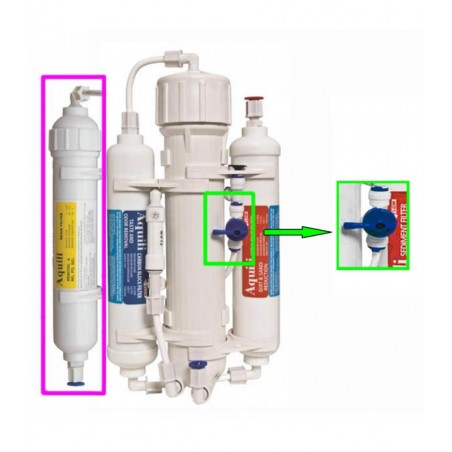

Plant GIA' ASSEMBLATO Osmosis 4 stages Aquili with flushing valve

AquiliAquili in-line osmosis plant at 4 stages 190 liters per day plus NO3 PO4 SiO2 filter with flushing valve for membrane washing.

DON'T YOU WANT TO GET RID OF THE IMPLE?

THIS IS THE JUST SERVICES FOR YOU!

HERE'S THE PLANT ASSEMBLED!

The reverse osmosis is a technology that exploits the capacity of certain semi-permeable membranes to separate water from dissolved substances.

Applying a certain pressure (that water network), you force water to cross the membrane; pure water (permeated) will thus be divided by water containing salts (concentrated)

The osmotic membrane that implements the most powerful feasible level (that of polyamide/polysolphon), acts as a barrier to not only inorganic salts and substances, but also towards organic substances of molecular weight greater than 100; it is therefore an excellent defense against micro pollutants, pesticides, pyrogenics, viruses and bacteria that were contained in the water.

This technology appeared on the water treatment market in recent times, has been rapidly affirming, and, in a few years, has been set thanks to its versatility, excellence of performance and simplicity of use.

• The membranes were tested at 25°, 4.8 bar, 2000 ppm as TDS.

• Due to the different operating conditions, compared to the ideals in which they were verified, real production is about half of the theoretical one.

Technical data

Osmotic water – Residual water the luminaires were set on the ideal and experienced ratio of 1 to 4.

Operating pressure 3 – 8 bar

Temperature 1 – 30 degrees centigrade

Quality member TFM Poliammide – Polisolfone

Salt reduction rate 98% - 99%

Values Exit water 10 – 40 microsiemens

The OSMO50 plant consists of:

Cartridge 5 micron in-line seeds

Carbon in-line cartridge treated with specific water purification acids

Osmotic membrane with a range of 50 gallons per day (1 gallon = 3,785 liters)

Filter to delete NO3 PO4 SiO2

Watch out for

Align the plant always and only to a pipe of cold water (maximum 30° C) otherwise it will worsen the deduction rate and the membrane can spoil itself before the time.

Check that the membrane is pushed well at the bottom, before screwing the cover of the container (4). (the central tube of the membrane must be aligned with the edge of the container without cover).

Do not force the fitting (especially the elbow fitting – Flow Restrictor ), but, if once started, the system showed losses, use the teflon.

Slide the water into the charcoal filter before connecting it to the membrane, so that it can purge any impurities present.

Osmotic water and residual water must always be able to flow freely; never close with faucets or similar things.

Protect the membrane from frost and drying. Once used, the membrane must no longer dry.

If the reverse osmosis system is not used for more than 10-15 days, use a protective solution that maintains the osmotic module efficiently by inhibiting the growth of bacteria and preventing the deposit of impurities (Preservation Fluid).

It is not possible with reverse osmosis to eliminate particularly high individual values, for example a high content of silicic anhydride or nitrate.

Do not leave the car unattended during use.

Do not use water for food use.

Always use original spare parts.

Regularly change the prefilter to sediment and carbon filter. The function of activated charcoal is to retain the chlorine which, if it passes, irreparably damages the membrane by tearing the microstructure. The salts will not be kept optimally and the value in microsiemens, of the outgoing water, will increase.

Calcium and magnesium tend to settle within the membrane by decreasing its productivity. Disinfection Powder disinfects thoroughly and eliminates all the incrustations (current impurities) restoring the efficiency of the plant.

Very useful, for proper aquarium management, is Minerals that enriches with mineral salts and trace elements osmotic water and all very tender waters.

The Ph value of the permeate is not predictable, high Ph values can be easily corrected downwards with CO2, if the Ph value is too low it is sufficient to air the water obtained abundantly.

Installation instructions

1 water input from the water network

2 Prefilter to Sedimentation

3 Filter with Active Carbon

4 Vessel - membrane container

5 Osmotic Member

6 Permeate – Osmotic water

7 Concentrated – Waste water with Flow Restrictor valve

8 Filter anti NO3-PO4-SiO2

In our system the water tap enters by means of the connection (agreement that is located inside the envelope), comes to a universal connection (1), and passes through a prefilter to Sedimentation (2) that holds the particles greater than 0.005 mm (5 microns). (Only the RO Classic and RO NPS models have the sedimentation filter, in the RO Basic models the carbon filter also performs the mechanical filter function of 5 microns). After this first purification the water is flowed into a cartridge with activated carbon (3) which removes chlorine and also eliminates traces of pesticides, herbicides, metals and, also, the bad taste and/or smell that water can free. After passing through the charcoal filter, the water is sent under pressure to a special membrane (5) which allows only pure water to pass. The substances that harden water and harmful ones such as salts, carbonates, sulphates, heavy metals, pesticides, and even bacteria and viruses are retained and rinse with residual water.

For mounting, the membrane should be inserted into its container so that the larger o-ring remains towards the cap, while the two small o-rings remain down.

To achieve the desired effect, the quality of the osmotic membrane is decisive; the membranes used in our appliances (polyamide/polysolphon) are extremely resistant to bacterial aggression, have long life, are easy to store and remain unchanged for years. Once treated, the water is pre-canalized in the central tube of the membrane and comes out, pure, through the central duct (6). For the installation, open the water tap and rinse the appliance for at least two hours, during this period check that in the channeling (7) at least a quadruple amount of concentrate on the osmotic water produced.

RO with NO3-PO4-SiO2 filter:

If you have an Osmosis system with NO3-PO4-SiO2 filter, before connecting the osmotic water outlet to the nitrate-phosphate-silicate filter (8), it is recommended to let the water flow for about 2-3 hours in order to completely eliminate the dry membrane preservative.

No reviews